roughing end mill depth of cut

For Taps Dies Cutting and Measuring Tools. Then let it haul ass.

Basic End Mills Technical Information Msc Industrial Supply Co

Ad Browse discover thousands of brands.

. I run 600SFM 006 IPT at up to 900 depth with a 750 endmill on F22 and A105. The depth of cut for 12 inch endmill in carbide with mild steal is the dia of the tool. This results in lower cutting pressures at a given radial depth of cut.

In-depth articles up-close photography and detailed illustrations Subscribe Now. Login Dear Customers Our supplier HTC is having substantial problems with supply chains due to Covid-19. Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions.

Freer Cutting that Demands Less Horsepower. They are designed to remove large amounts of material quickly and more efficiently than standard end mills. Order At Grizzly Now.

Now choose the right surface feet per minute SFM or surface meters per minute SMM. Design that Virtually Eliminates Flute Packing and Obstruction. Roughers have chip-breaker cutting edges the peaks.

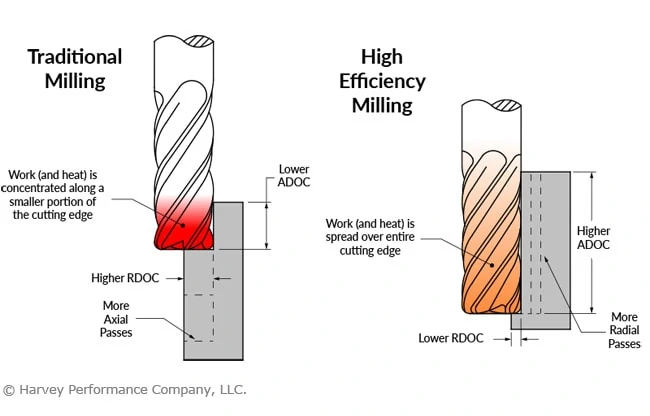

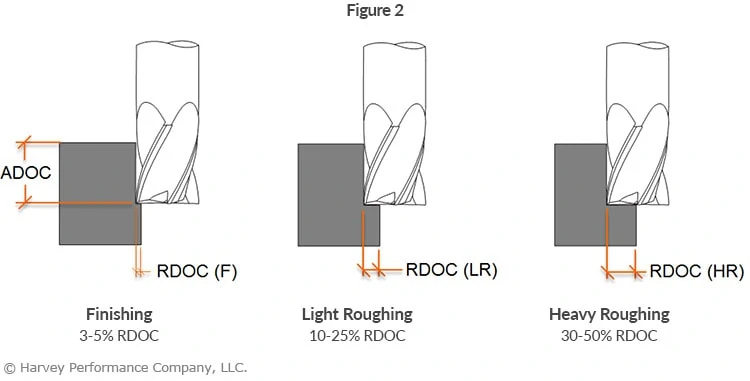

Made of solid carbide these end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. For high-speed roughing width of cutis usually set at somewhere between 5 and 10 percent of the cutting tool diameter. High-Performance Solid Carbide Roughing End Mills KenCut RR Solid Carbide End Mill for Roughing of Steels Stainless Steel Cast Iron High Temperature Alloys.

Up to 16 cash back Roughing End Mills. For example the average recommended feed rate for a 050-inch tool is approximately 0002 inch per tooth. Up to 16 cash back Reduce your cutting forces by reducing speed andor feed or axial andor radial depth of cut Increase your systems rigidity by changing over to a stub length end mill or improving your workpiece fixturing Change geometry - use an end mill with variable flute spacing or a small circular margin Poor surface finish.

As for cutting slots with end mills I have always found most success using a two stage cut. Roughing End Mills have scallops on the cutting edges which cause the chips to break into smaller segments. End Mills cut rotationally in a horizontal or lateral side to side direction whereas a drill bit only cuts straight down vertically into the material.

This setting will impact RCT calculations as well. Cobalt roughing end mills are designed to withstand heat and abrasion and can be run at higher production rates without sacrificing tool life. I use the Dominator endmills by IMCO.

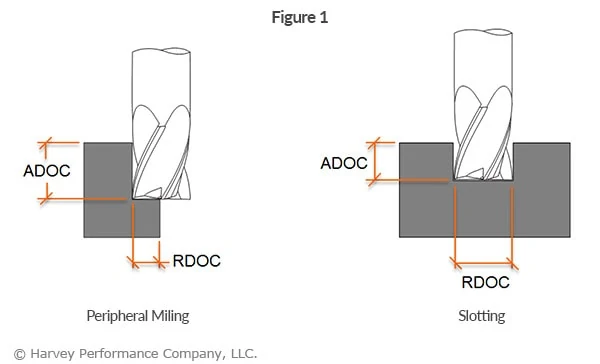

Ad Inch and Metric Mills - Single or Double End Roughing Mini Long Ball End. Read customer reviews find best sellers. CLF based on the radial depth of cut.

Their extreme hardness means they are brittle so a highly rigid setup such as a CNC machine is necessary to prevent the end mill from. Stabilizing cutting edge geometry. Heavy cuts can be achieved because our roughing end mills have a much higher effective feed per tooth than a conventional end mill.

SFM divided by dia multi by 382 multi by IPR. 1771 in L3 Usable Length. So if I am cutting a 38 slot I do my setup and cut the slot first with a 14 end mill.

The tooth design and flute construction minimizes deflection and maximizes chip ejection. Multi-Cut end mills are specifically designed for high-performance roughing operations. Mill Diameter Decimal Inch.

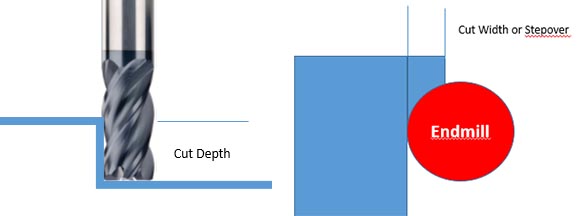

Ad Over 30 Years Of Quality Industrial Machinery Equipment. Length of Cut Inch. A finer finish will require less depth of cut.

So I use old mills or roughing end mills to hog out the majority of the. Due to variable spacing of flutes combined with the NR roughing profile vibrations cutting forces are minimized and metal removal rates are maximized. Volumes of material can be removed at high cutting speed.

Your machines spindle will only tolerate a certain depth of cut before the machine starts to falter too so you. Stability in Aggressive Applications. The SSDH series achieves superior chip flow and evacuation through the introduction of chip-release flute form technology and a unique inter-flute helical transition all.

45 high helix flute design. Shop Our Huge Selection of Fine Machinery. Length of Cut Decimal Inch.

Insertable carbide end mills require a certain rather narrow range of depths of cut. Speeds and feeds charts for end mills from The Carbide End Mill Store. 650000 mm L3 Usable Length.

CHOOSING THE CORRECT ANGLE END MILL FOR YOUR JOB Helix angles generally come as low as 12 to as high as 60. Order Your Industrial Tools At Grizzly. When I enter the cut I go 003 IPT.

Carbide Square End Mills. Cobalt roughing end mills are designed. Increasing the helix angle improves stock removal and is useful in machining at increased speeds and feeds.

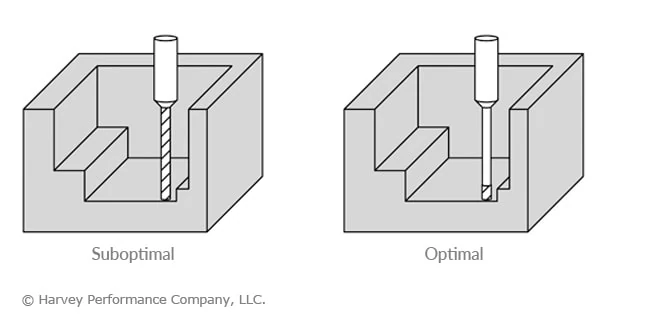

Extra long end mills require a shallower depth of cut because they flex more than stub length end mills which can deal with a greater depth of cut. AP1MAX 1st Maximum Cutting Depth. This means a 050-inch end mill will be engaged 0025 to 0050 inch.

Normally a 20 reduction in effective horsepower is used. 1210000 mm L Overall Length. Vibration dampening variable flute spacing.

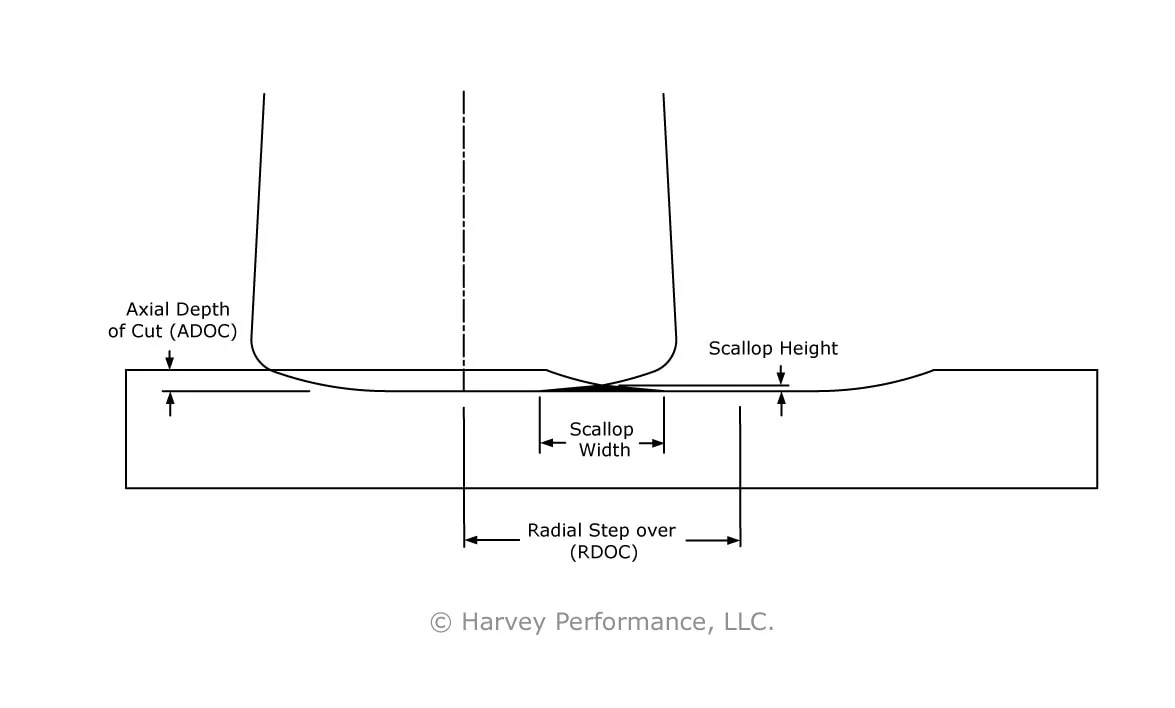

Endmills are available in a wide variety of lengths diameters flutes and types and are chosen according to the material they are cutting and the surface finish required for the project. Depth of cut 0050 0100 Step Over 0400 0400 RPM 2200 4000 Feed rate 352 960 Metal removal rate in cubic inches per minute 0704 03840 In this pocketing application involving a 1-inch tool performing Z-level roughing in P20 a ball cutter achieved five times the metal removal rate of a toroid tool. 2559 in L Overall Length.

The distance between scallops is referred to as pitch. Most general purpose end mills use between a 25 and 30 angle where basic sharpness and cutting edge strength is maintained.

Basic End Mills Technical Information Msc Industrial Supply Co

Amazon Com Accusize Industrial Tools 3 4 Fine Tooth M42 8 Cobalt Tialn Roughing End Mill 3 4 Shk Dia 1 5 8 Flute Length 3 3 4 Oal 4 Flute 1104 0034 Industrial Scientific

Basic End Mills Technical Information Msc Industrial Supply Co

8 Ways You Re Killing Your End Mill In The Loupe

8 Ways You Re Killing Your End Mill In The Loupe

End Mill An Overview Sciencedirect Topics

Endmill Selection Guide Redline Tools Redline Tools

Tialn Coated M42 8 Cobalt Roughing End Mills Standard Tooth Accusize

Optimize Depth Of Cut And Stepover For Better Cnc Milling

A Machinist S Guide To Trochoidal And Peel Milling Make It From Metal

Cnc Programming Archives Page 2 Of 2 Harvey Performance Company

Troubleshooting Tips Archives Page 2 Of 3 Harvey Performance Company

Iscar Cutting Tools Metal Working Tools Milling Plunging Recessing

Cutting Conditions For Rough Cutting Download Table

The Secret Mechanics Of High Feed End Mills In The Loupe

The Secret Mechanics Of High Feed End Mills In The Loupe

End Mill An Overview Sciencedirect Topics

Basic End Mills Technical Information Msc Industrial Supply Co